Mill & Cogeneration Plant Overview

This facility includes a fully integrated sugar mill and a 36.5 MW cogeneration plant designed for efficient energy recovery and continuous operation.

Every component has been maintained and cataloged for operational readiness, representing the complete infrastructure for cane processing, sugar production, and power generation.

Every component has been maintained and cataloged for operational readiness, representing the complete infrastructure for cane processing, sugar production, and power generation.

Complete Equipment Inventory

Evaporators

VB13-100 — Evaporator Silver Robert Type Body #1 — 28,600 sq ft

VB13-101 — Evaporator Silver Robert Type Body #2 — 20,000 sq ft

VB13-102 — Evaporator Silver Robert Type Body #3 — 12,000 sq ft

VB13-103 — Evaporator Silver Robert Type Body #4 — 15,000 sq ft

VB13-104 — Evaporator Silver Robert Type Body #5 — 21,999 sq ft

VB13-101 — Evaporator Silver Robert Type Body #2 — 20,000 sq ft

VB13-102 — Evaporator Silver Robert Type Body #3 — 12,000 sq ft

VB13-103 — Evaporator Silver Robert Type Body #4 — 15,000 sq ft

VB13-104 — Evaporator Silver Robert Type Body #5 — 21,999 sq ft

Vacuum Pans

VB13-105 — Pan Vacuum w/ Heat Surface — 3,800 cu ft

VB13-106 — Pan Vacuum (Continuous) Fletcher Smith #11 — 3,350 cu ft

VB13-107 — Pan Vacuum (Batch) Fletcher Smith #12 — 3,530 cu ft

VB13-401 — Pan Vacuum Fletcher Smith S/S #12 — 1,500 cu ft

VB13-402 — Pan Vacuum Hornor S/S #13 — 3,500 cu ft

VB13-403 — Pan Vacuum Hornor S/S #14 — 3,500 cu ft

VB13-501 — Pan Vacuum Hornor S/S #15 — 3,500 cu ft

VB13-50 — Pan Vacuum Hornor (Continuous) #16 — 1,000 cu ft

VB13-106 — Pan Vacuum (Continuous) Fletcher Smith #11 — 3,350 cu ft

VB13-107 — Pan Vacuum (Batch) Fletcher Smith #12 — 3,530 cu ft

VB13-401 — Pan Vacuum Fletcher Smith S/S #12 — 1,500 cu ft

VB13-402 — Pan Vacuum Hornor S/S #13 — 3,500 cu ft

VB13-403 — Pan Vacuum Hornor S/S #14 — 3,500 cu ft

VB13-501 — Pan Vacuum Hornor S/S #15 — 3,500 cu ft

VB13-50 — Pan Vacuum Hornor (Continuous) #16 — 1,000 cu ft

Crystallizers

VB13-108 — Crystallizer Vertical Fletcher Smith #10 — 7,000 cu ft

VB13-109 — Crystallizer Vertical Fletcher Smith #1 — 7,000 cu ft

VB13-110 — Crystallizer Vertical Fletcher Smith #12 — 7,000 cu ft

VB13-111 — Crystallizer SS Dorr-Oliver #1 – 96" × 16' — 400 sq ft

VB13-112 — Crystallizer SS Dorr-Oliver #2 – 96" × 16' — 400 sq ft

VB13-113 — Crystallizer SS Dorr-Oliver #3 – 96" × 16' — 400 sq ft

VB13-114 — Crystallizer SS Dorr-Oliver #4 – 96" × 16' — 400 sq ft

VB13-115 — Crystallizer SS Dorr-Oliver #5 – 96" × 16' — 400 sq ft

VB13-116 — Crystallizer SS EMCO – 96" × 16' — 400 sq ft

VB13-109 — Crystallizer Vertical Fletcher Smith #1 — 7,000 cu ft

VB13-110 — Crystallizer Vertical Fletcher Smith #12 — 7,000 cu ft

VB13-111 — Crystallizer SS Dorr-Oliver #1 – 96" × 16' — 400 sq ft

VB13-112 — Crystallizer SS Dorr-Oliver #2 – 96" × 16' — 400 sq ft

VB13-113 — Crystallizer SS Dorr-Oliver #3 – 96" × 16' — 400 sq ft

VB13-114 — Crystallizer SS Dorr-Oliver #4 – 96" × 16' — 400 sq ft

VB13-115 — Crystallizer SS Dorr-Oliver #5 – 96" × 16' — 400 sq ft

VB13-116 — Crystallizer SS EMCO – 96" × 16' — 400 sq ft

Cogeneration Plant

VB13-200 — Cogeneration Plant — 36,500 kW (coal / bagasse / oil-fired)

Includes boilers, turbines, alternators, condensers, feed-water systems, cooling towers, switchgear, MCCs, and full control assemblies.

Includes boilers, turbines, alternators, condensers, feed-water systems, cooling towers, switchgear, MCCs, and full control assemblies.

Cane Crushing and Preparation

VB13-300 — Cane Crushing Plant (New Walkers) — 7,200 TPD

VB13-301 — Swing Knife Set — for 7,200 TPD

VB13-302 — Cane Shredder (New Walkers) — 7,200 TPD

VB13-303 — Mill #1 – New Walkers 6-Roll — 78" × 40"

VB13-304 — Mill #2 – New Walkers 6-Roll — 78" × 40"

VB13-305 — Mill #3 – New Walkers 6-Roll — 78" × 40"

VB13-306 — Mill #4 – New Walkers 6-Roll — 78" × 40"

VB13-307 — Mill #5 – New Walkers 8-Roll — 78" × 40"

VB13-301 — Swing Knife Set — for 7,200 TPD

VB13-302 — Cane Shredder (New Walkers) — 7,200 TPD

VB13-303 — Mill #1 – New Walkers 6-Roll — 78" × 40"

VB13-304 — Mill #2 – New Walkers 6-Roll — 78" × 40"

VB13-305 — Mill #3 – New Walkers 6-Roll — 78" × 40"

VB13-306 — Mill #4 – New Walkers 6-Roll — 78" × 40"

VB13-307 — Mill #5 – New Walkers 8-Roll — 78" × 40"

Centrifugals & Sugar Processing

VB13-404 — Western States Titan SSB-1270 — 54" × 40" (batch)

VB13-503 — Western States G-15-6 — 50" × 36" (batch)

VB13-504 — Western States G-15-6 — 50" × 36" (batch)

VB13-503 — Western States G-15-6 — 50" × 36" (batch)

VB13-504 — Western States G-15-6 — 50" × 36" (batch)

Filtration & Syrup Auxiliary Systems

VB13-505 — Tekleen Syrup Self-Cleaning Filters (Skid of 10)

Includes piping, pumps, condensate tanks, agitators, and catwalk assemblies (numerous minor items not individually tagged).

Includes piping, pumps, condensate tanks, agitators, and catwalk assemblies (numerous minor items not individually tagged).

Puunene Fire Pumps

EQ — Description

4500 — Puunene Primary Fire Pump

4501 — Puunene Jockey Pump

4502 — Puunene Primary Fire Pump Controller

4503 — Puunene Secondary Fire Pump

4504 — Puunene Secondary Fire Pump Diesel Engine

4506 — Puunene Fire Main Hydrants (on Fire Loop)

4507 — Puunene Fire Yard Water Hydrants

4508 — Puunene Post Indicator Valves

4509 — Puunene Key Gate Valves

4510 — Puunene Risers

4511 — Puunene Piping Inside Building

4512 — Puunene Piping Outside Buildings

4513 — Puunene Outside Fire Boxes

4514 — Puunene Mill Fire Boxes

4515 — Puunene Power Plant Fire Boxes

4516 — Puunene Mixing Plant Fire System

4517 — Puunene Transportation Fire System

4518 — Puunene Cane Hauler Fire System

4519 — Puunene Miscellaneous Fire System Components (sprinkler heads, hand valves, etc.)

4500 — Puunene Primary Fire Pump

4501 — Puunene Jockey Pump

4502 — Puunene Primary Fire Pump Controller

4503 — Puunene Secondary Fire Pump

4504 — Puunene Secondary Fire Pump Diesel Engine

4506 — Puunene Fire Main Hydrants (on Fire Loop)

4507 — Puunene Fire Yard Water Hydrants

4508 — Puunene Post Indicator Valves

4509 — Puunene Key Gate Valves

4510 — Puunene Risers

4511 — Puunene Piping Inside Building

4512 — Puunene Piping Outside Buildings

4513 — Puunene Outside Fire Boxes

4514 — Puunene Mill Fire Boxes

4515 — Puunene Power Plant Fire Boxes

4516 — Puunene Mixing Plant Fire System

4517 — Puunene Transportation Fire System

4518 — Puunene Cane Hauler Fire System

4519 — Puunene Miscellaneous Fire System Components (sprinkler heads, hand valves, etc.)

Puunene Factory V-Belts

Cane Cleaner

6117 — Dorrco — BX112 — 4 each

6148 — Warman — B112 — 4 each

6102 — Hydro Scroll Upper — A48 — 2 each

6102 — Hydro Scroll Lower — A48 — 2 each

6111 — Dorrco — AP66 — 2 each

Crushing Plant

6071 — Belt Conveyor — B105 — 5 each

6296 — Rotary Stainer — HC3VX670 — 3 each

7155 — Magnet — B103 — 3 each

7188 — A3 Sala Pump — 3VX425 — 3 each

7190 — A5 Sala Pump — 3VX500 — 3 each (Paia side)

7192 — A5 Sala Pump — 3VX450 — 2 each (Wailuku side)

7290 — B5 Sala Pump — 3VX425 — 2 each

6071 — Belt Brush Headshaft — A60 — 2 each

6227 — B Shredder Turning Device — B42 — 4 each

6296 — Rotary Stainer Scroll — 3VX800 — 3 each

6117 — Dorrco — BX112 — 4 each

6148 — Warman — B112 — 4 each

6102 — Hydro Scroll Upper — A48 — 2 each

6102 — Hydro Scroll Lower — A48 — 2 each

6111 — Dorrco — AP66 — 2 each

Crushing Plant

6071 — Belt Conveyor — B105 — 5 each

6296 — Rotary Stainer — HC3VX670 — 3 each

7155 — Magnet — B103 — 3 each

7188 — A3 Sala Pump — 3VX425 — 3 each

7190 — A5 Sala Pump — 3VX500 — 3 each (Paia side)

7192 — A5 Sala Pump — 3VX450 — 2 each (Wailuku side)

7290 — B5 Sala Pump — 3VX425 — 2 each

6071 — Belt Brush Headshaft — A60 — 2 each

6227 — B Shredder Turning Device — B42 — 4 each

6296 — Rotary Stainer Scroll — 3VX800 — 3 each

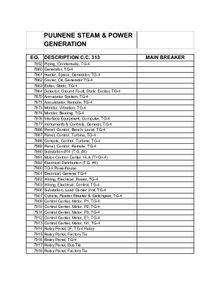

Puunene Power Production

EQ — Description / Notes

6001–7850 — Comprehensive list of Puunene Power Plant components, including:

6001–7850 — Comprehensive list of Puunene Power Plant components, including:

- Turbo Generators & Condensers: Multiple TG units with pumps, ejectors, and vacuum systems.

- Boiler Systems: Boilers #1–#3, including furnaces, grates, burners, fans, dust collectors, blowers, feedwater pumps, deaerators, condensate tanks, air compressors, fuel oil systems, and instrumentation.

- Electrical & Control Systems: MCCs, substations, tie lines, UPS systems, panels, and control instrumentation.

- Bagasse Handling: Conveyors, elevators, feeders, fluffers, and scales.

- Fuel & Water Systems: Fuel oil pumps, caustic systems, scrubbers, condensate systems, and cooling water setups.

- Mobile & Shop Equipment: Loaders, trailers, tractors, welding machines, and shop tools.

- Turbine TG-4 Systems: Including hydraulic power systems, lubrication equipment, condensers, ejectors, pumps, and steam piping.

Interested in Purchasing?

Qualified buyers are encouraged to contact Hawaiian Commercial and Steel LLC for details, pricing, and inspection opportunities.